Copper coatings

Our HMT-Metal process can apply copper films with >25% of the bulk copper conductivity on complex shaped parts and a wide range of materials. The process can either coat the entire part’s surface, including internal channels and undercuts or be applied selectively. Our HMT-Metal process is ideally suited for those applications where the use of bulk copper is not required and would be impossible or uneconomic. Using this process in combination with 3D printed photopolymer parts, for example, previously unmanufacturable mm-wave components with sub-µm smooth surfaces can now be made, and it opens the design freedom of additive manufacturing to cases where CNC machining or bulk metal 3D printing can’t deliver.

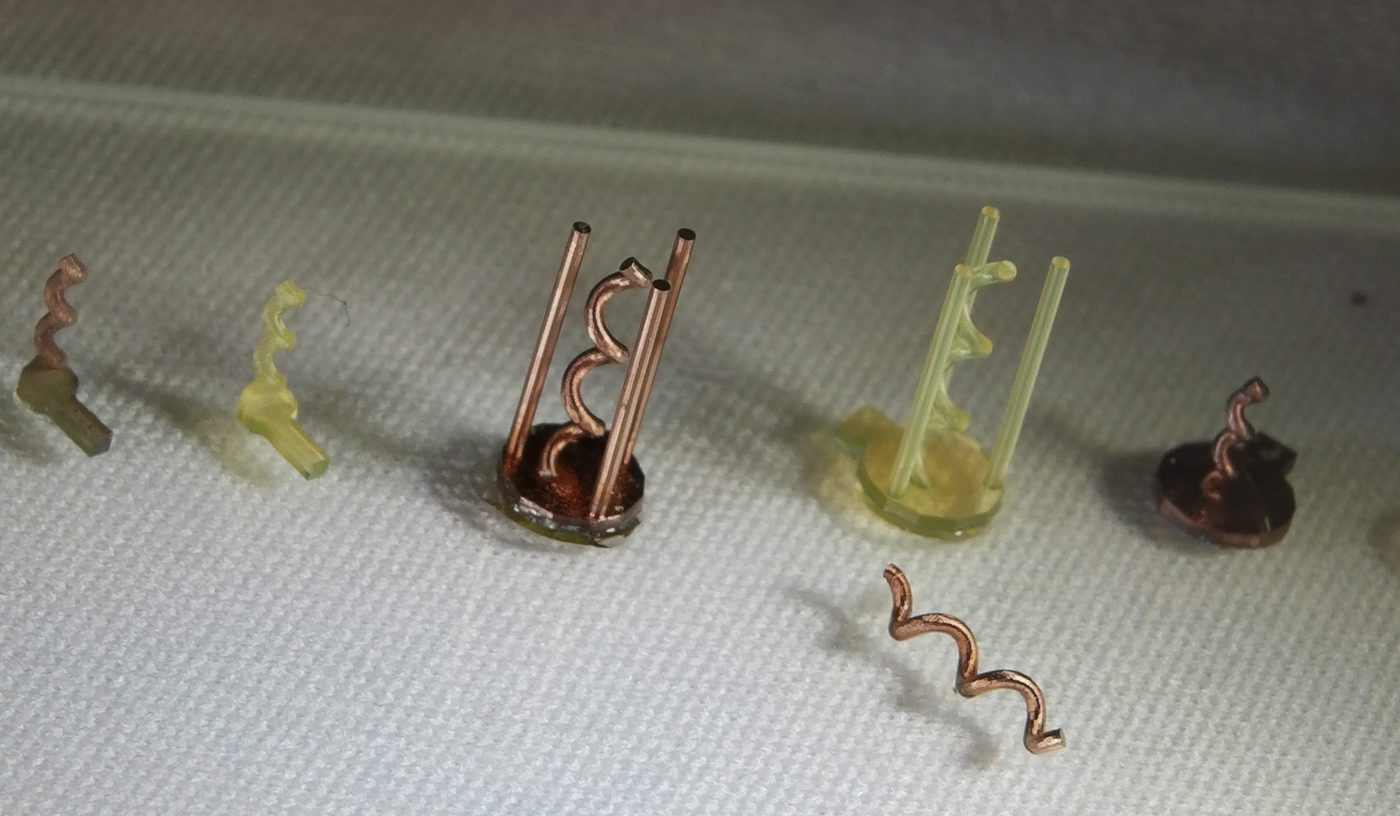

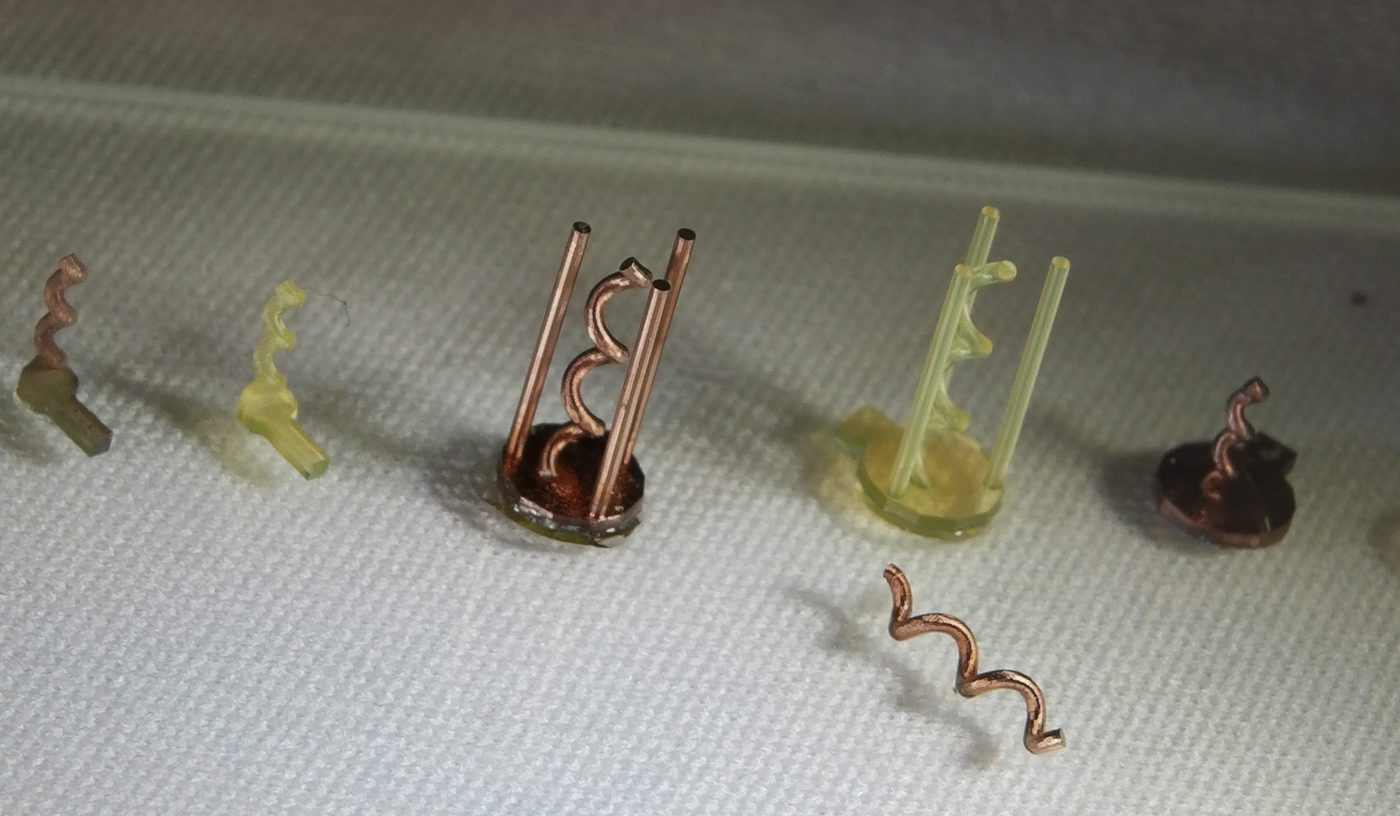

Importantly, the copper coating can also be applied selectively to properly designed parts. When applied this way to 3D microprinted geometries, several independent metal features (lines, ares, tunnels,.) for interconnects, vias, or similar applications can be created.

Conservative Specifications:

(Please note that specifications are constantly evolving and may be design-specific and mutually dependent.)

Reach out now to get a quote for the coating of your 3D precision- or micro-parts.

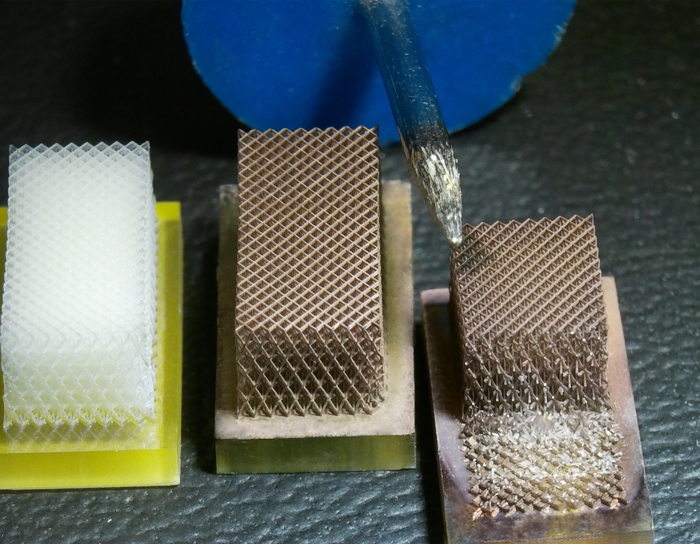

Illustration of the 3D capabilities of the HMT Metal process. From left to right: Polymer lattice, an identical polymer lattice coated with copper and a metal-coated and subsequentially cut polymer lattice. The individual lattice struts are 50 µm wide and located at 500 µm distance from their neighbors. The cut through the middle of the right-most lattice clearly shows the ability of Horizon’s coating processes to reach even deeply recessed sections of parts.

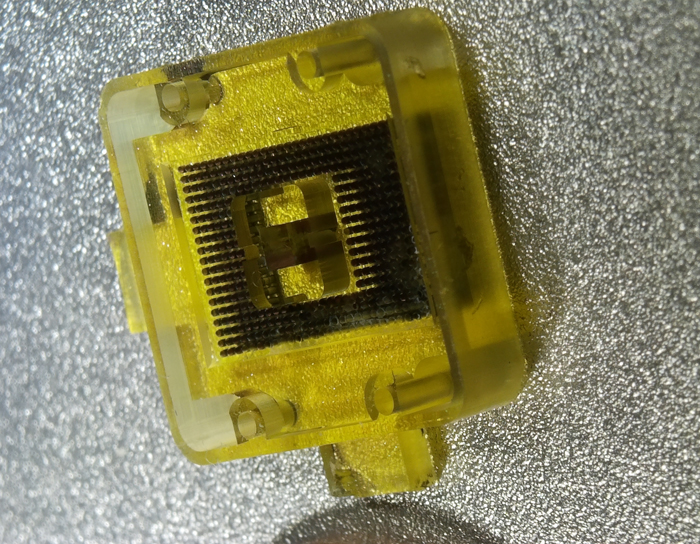

3D printed and subsequently metallized, monolithic testsocket with heat resistant polymer body and integrated individual metallic leads made by selective coating.

Please contact us if you have any questions regarding our services. A member of our team will be in touch with you as soon as possible