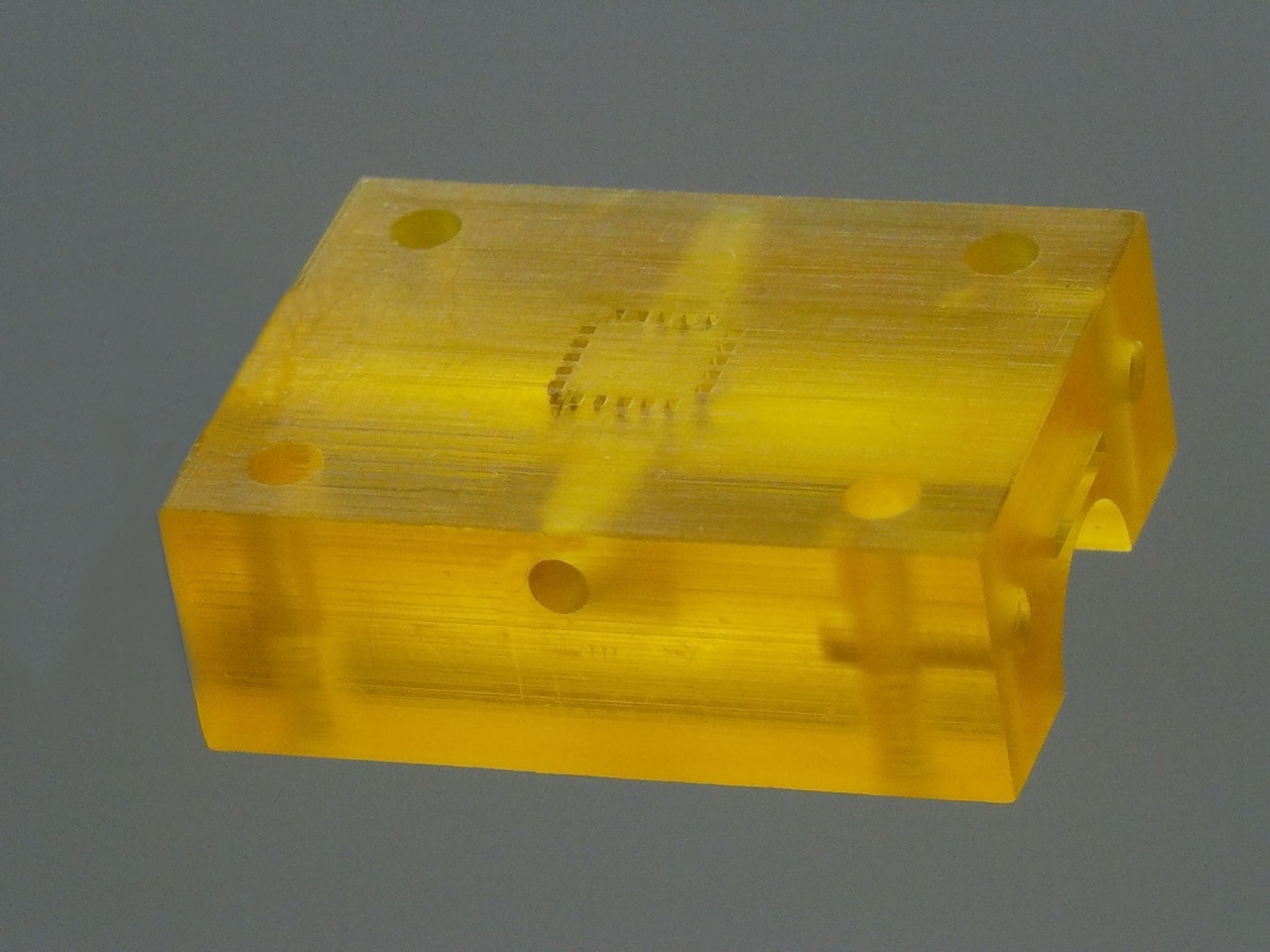

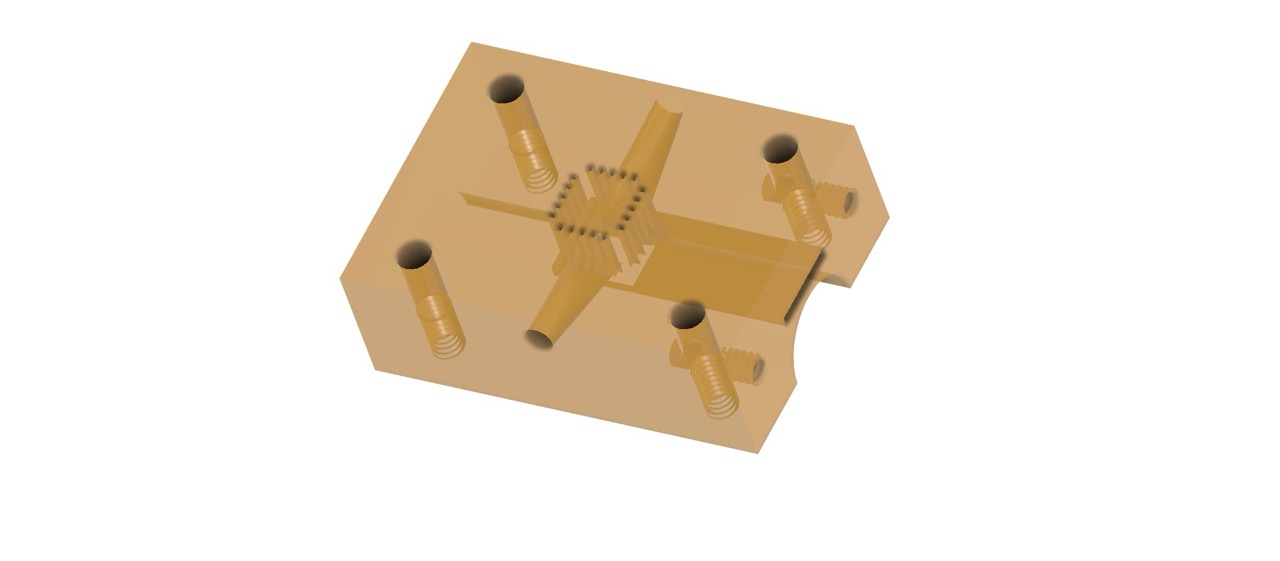

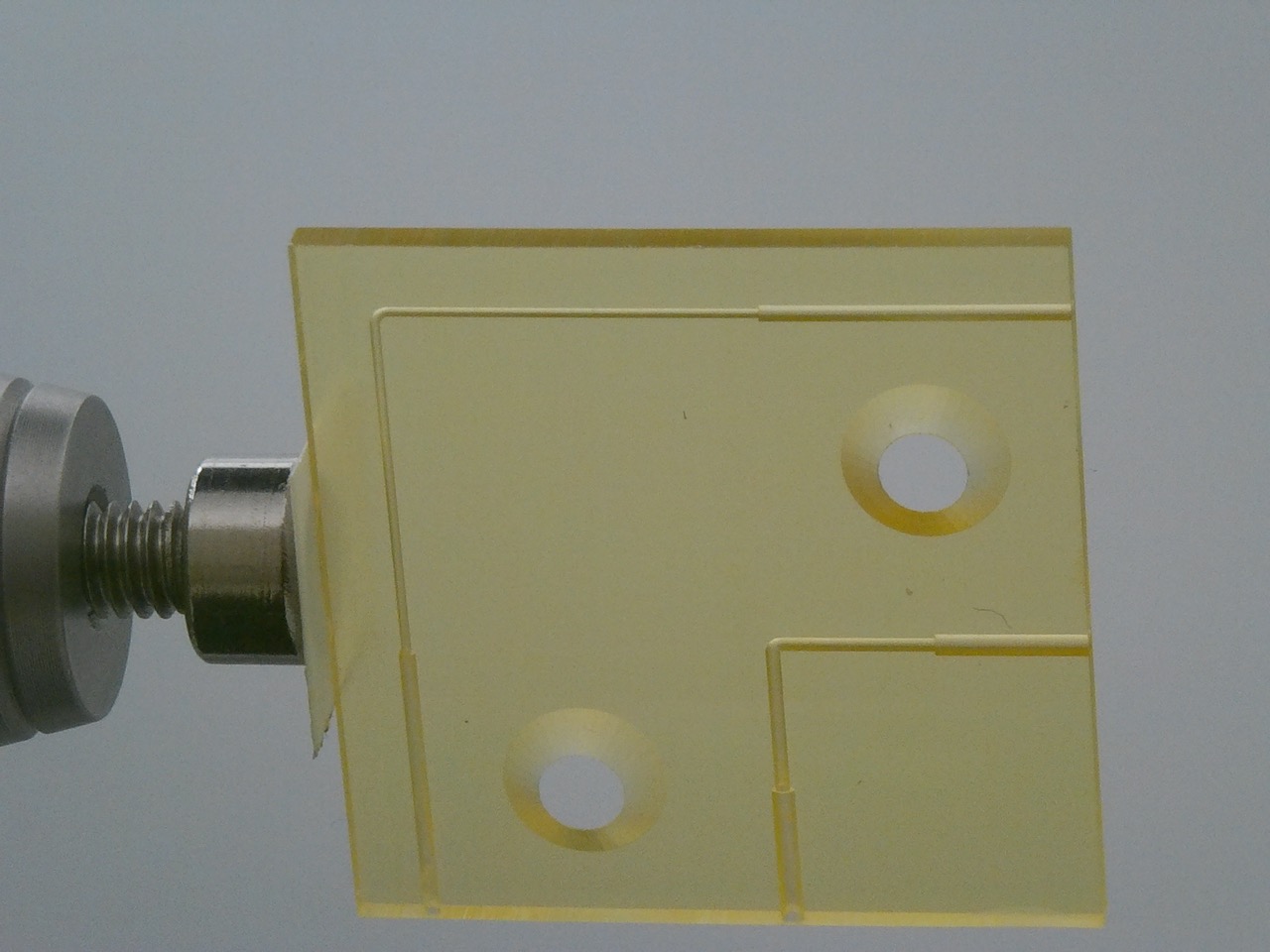

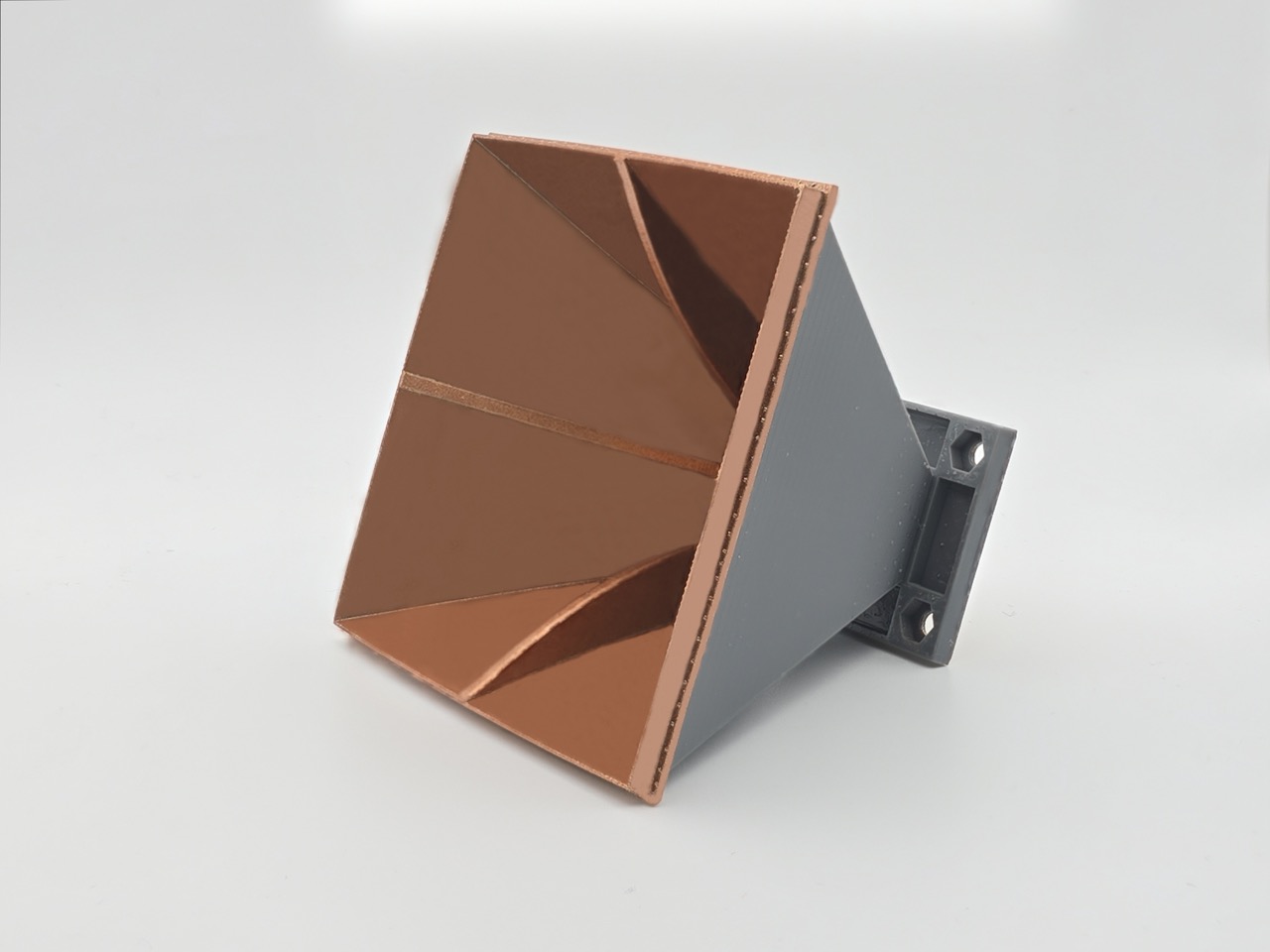

Our in-house expertise in micro-3D printing and coating workflows means that we don’t just print parts — we help you optimise them for performance and manufacturability. Whether you supply the design or partner with us from the concept stage, we ensure your components are developed with the full benefits of micro-AM in mind: miniaturisation, functional integration, freedom from supports, and even area-selective coatings.

We guide design decisions to account for complex factors such as shrinkage, rinsing behaviour, material selection, part orientation, and removal of supports — all of which impact surface quality and precision. Our metrology capabilities cover optical microscopy, SEM, and micro-CT.