Precision Microfabrication for Next Generation Devices

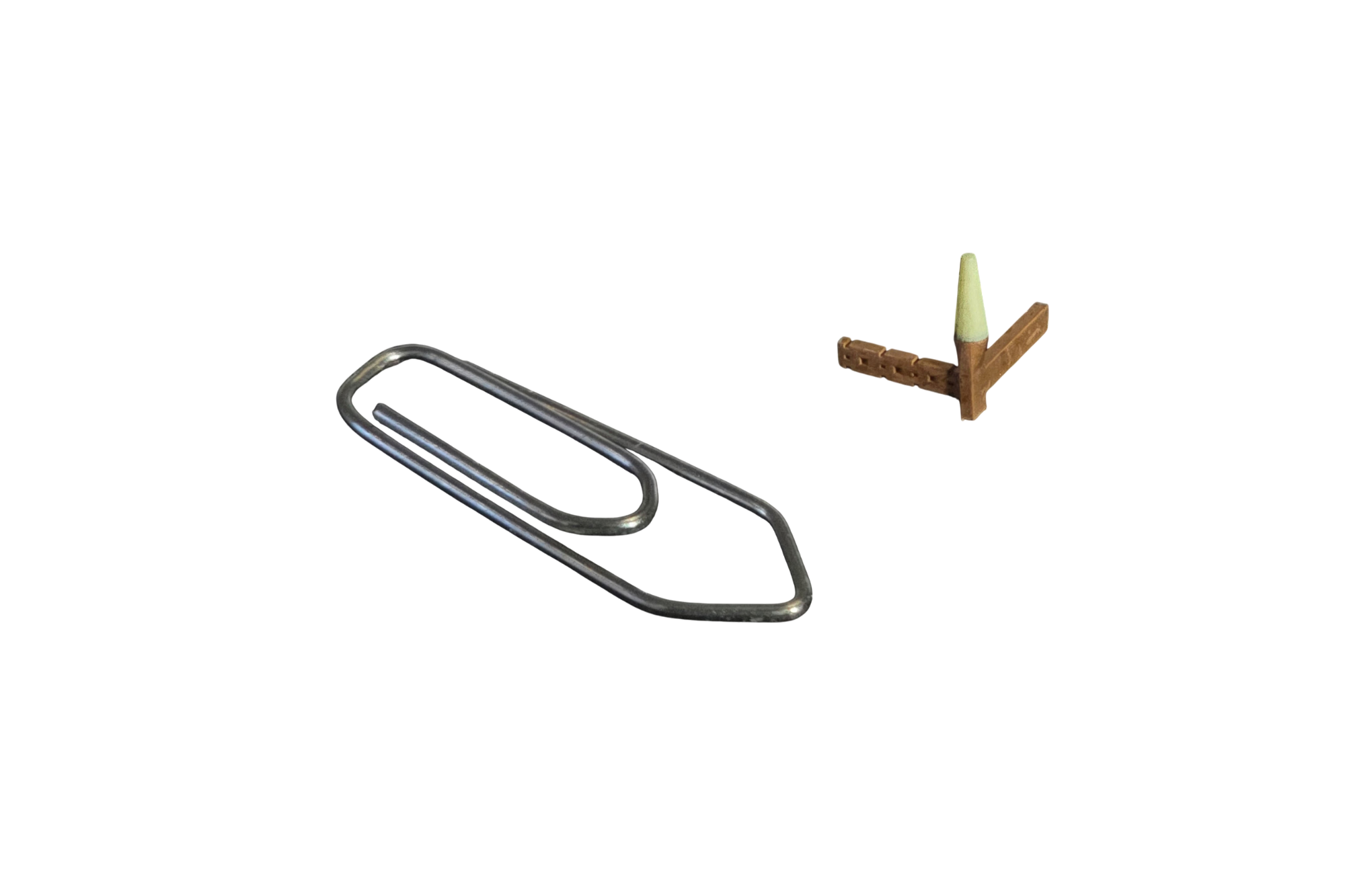

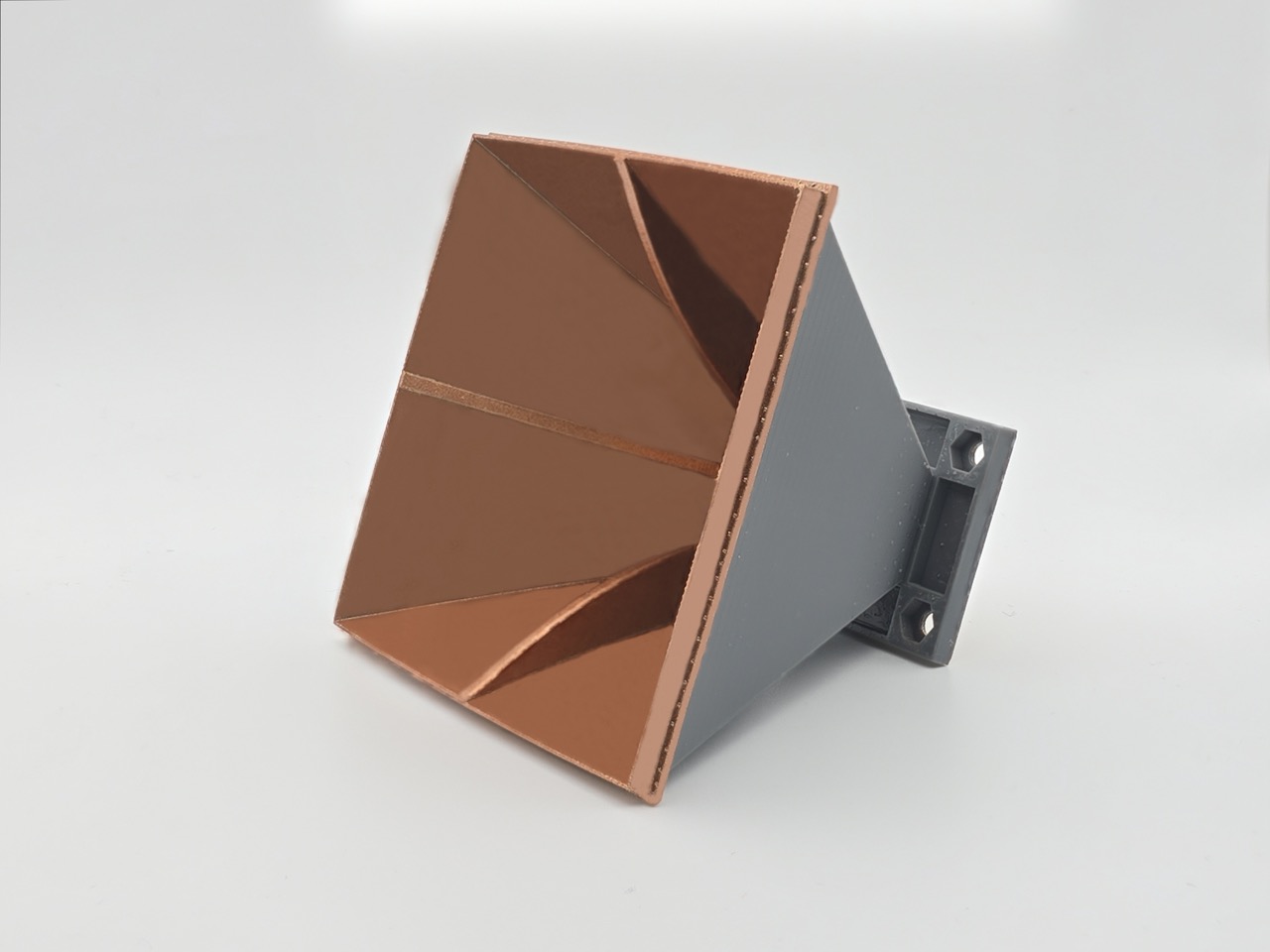

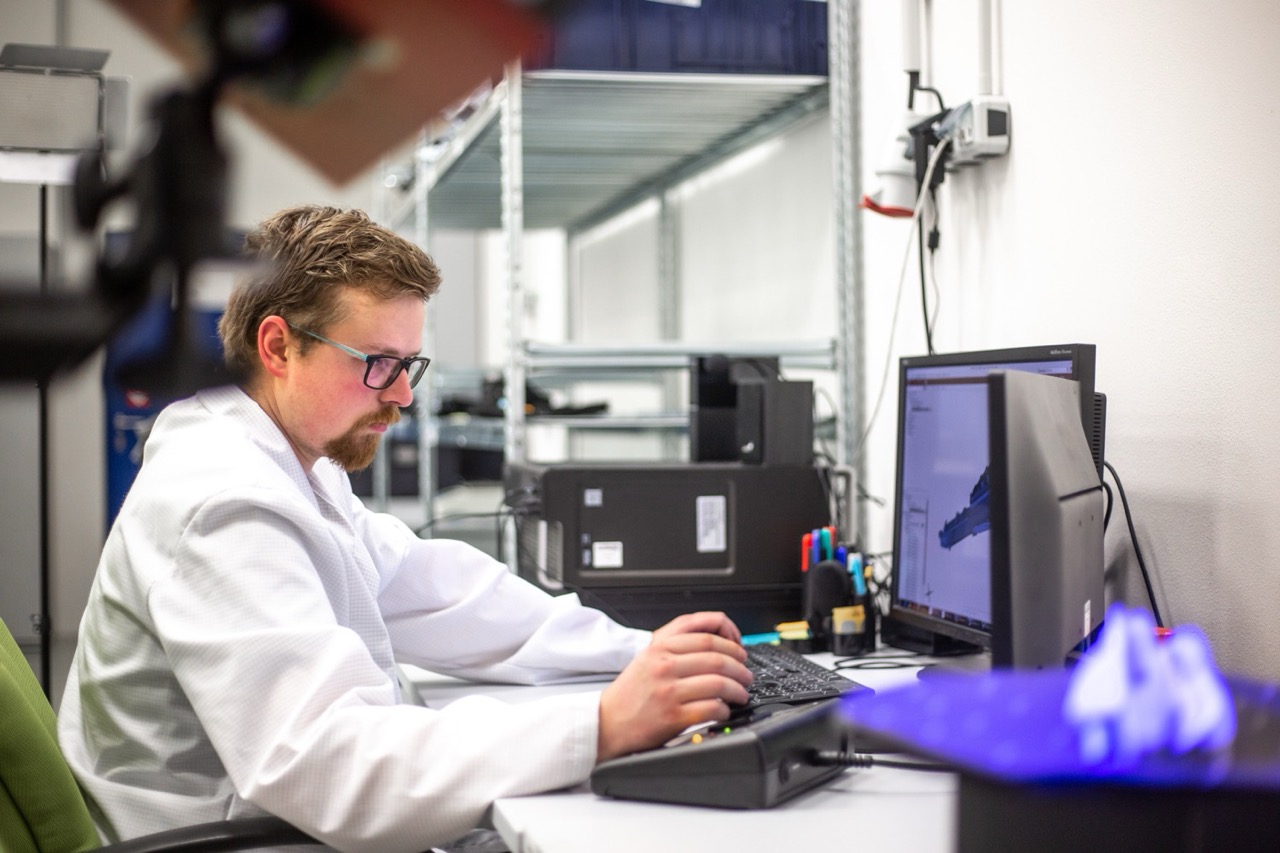

Horizon delivers industry-leading microfabrication services and products by combining precision 3D printing with advanced coating and metallisation technologies.

Our in-House process enables the creation of highly functional microscale components — whether for next-generation antenna structures in RF and microwave applications or for customers seeking scalable, contract-based manufacturing. We bridge design freedom and performance with production readiness across multiple industries.

Explore our capabilities through one of the areas below.